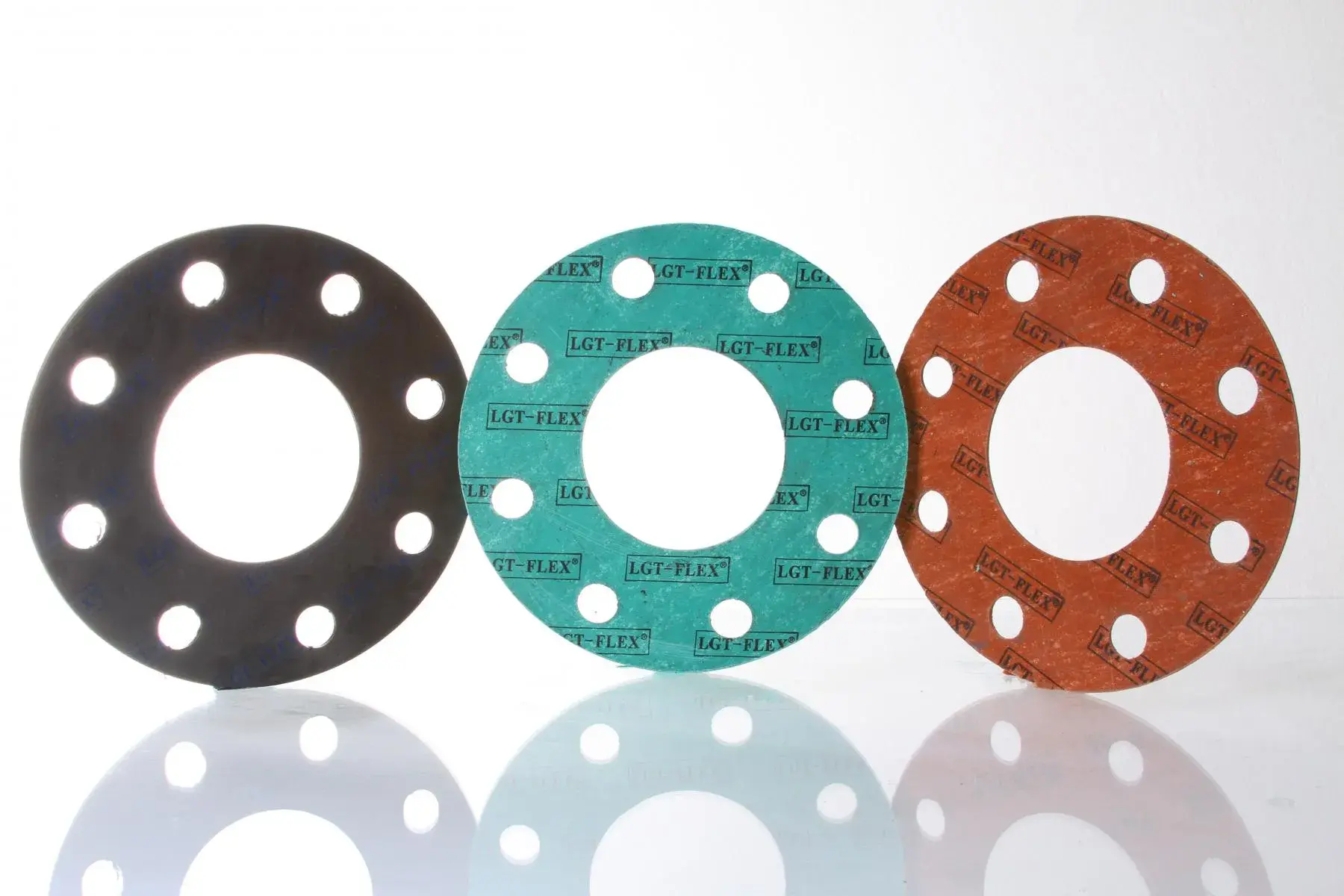

The juntas KLINGERIT are a type of sealing gasket with high quality materials, manufactured from compressed fibers, agglomerated and bonded together with synthetic rubber, usually acrylonitrile butadiene rubber and NBR.

Used in a wide variety of applications in the sealing industry. These gaskets are designed to provide a secure and durable seal between two surfaces, preventing leakage and fluid loss.

KLINGERIT gaskets are made of a specific sealing material, which can be a KLINGERIT compressed cardboard, a KLINGERIT fiberglass material or a KLINGERIT graphite material. These materials are designed to be highly resistant to deformation and wear, allowing them to maintain an effective seal even under high pressure and temperature conditions.

MANUFACTURING OF KLINGER SEALS

To manufacture a KLINGERIT gasket, you start with a sheet of the chosen sealing material, which is cut to the required shape and size. The gasket is then perforated to suit the specific application in which it will be used. These perforations can include holes for fasteners, fluid passages and any other features needed to suit the specific application.

Once the gasket has been cut and drilled, it can be installed in place in the corresponding application. When the gasket is tightened with the appropriate set screws, it compresses and conforms to the surfaces to be sealed, creating a tight, durable seal.

WHERE ARE THEY USED?

KLINGERIT gaskets are used in a wide variety of applications in the sealing sector, including the chemical industry, food industry, petrochemical industry and many others. These gaskets are suitable for sealing a wide variety of fluids, including gases, liquids and chemicals, and can be used in applications involving high temperatures and pressures among the most common:

In the chemical industry: KLINGERIT gaskets can be used to seal pipelines and equipment carrying corrosive and hazardous chemicals, such as strong acids and bases. KLINGERIT gaskets can withstand extreme temperatures and pressures, making them ideal for applications in the chemical industry.

In the food industry: KLINGERIT gaskets are used to seal equipment and pipelines that transport food and beverages. These gaskets are specifically designed to be safe and non-contaminating, and can withstand high temperatures and pressures without deterioration.

In the petrochemical industry: KLINGERIT gaskets are used to seal pipelines and equipment transporting petroleum products and natural gas. These gaskets are highly corrosion resistant and can withstand high temperatures and pressures, making them ideal for use in the petrochemical industry.

In the energy industry: KLINGERIT gaskets are used to seal equipment and pipelines in thermal and nuclear power plants. These gaskets are capable of withstanding extreme temperatures and pressures, which makes them suitable for use in highly demanding conditions.

In the automotive industry: KLINGERIT gaskets are used to seal engine components such as the cylinder head and exhaust manifold. These gaskets are able to withstand high temperatures and vibrations, making them ideal for use in the automotive sector.

MOST COMMON KLINGERIT GASKETS

- Klingerit C-4400: This is a cardboard gasket with steel mesh reinforcement and an NBR (nitrile rubber) binder for general low pressure and moderate temperature applications.

- Klingerit C-4500: This cardboard gasket contains graphite fibers and fillers, which improve its sealing properties in high pressure and temperature applications.

- Klingerit C-4430: This cardboard gasket is made of fibers with graphite and an NBR binder, which provides excellent chemical and thermal resistance for applications with aggressive chemicals.

- Klingerit C-8200: This cardboard gasket with steel mesh reinforcement and an SBR (styrene-butadiene rubber) binder is used in high-pressure, high-temperature water and steam applications.

- Klingerit C-4324: This cardboard gasket with stainless steel mesh reinforcement and an NBR binder is resistant to oils, fuels and coolants. It is used in low pressure and moderate temperature applications.

- Klingerit C-8207: This cardboard gasket with steel mesh reinforcement and an NBR binder is suitable for high-pressure, high-temperature steam and chemical applications.

- Klingerit C-4433: This cardboard gasket with stainless steel mesh reinforcement and an NBR binder is resistant to aggressive chemicals and is used in high pressure and temperature applications.

HOW TO MAINTAIN A KLINGERIT CARDBOARD GASKET AND PROLONG ITS SERVICE LIFE?

Below, we will provide the main steps to keep Klingerit cardboard gaskets in good condition and ensure that they function properly throughout their service life.

- Adequate storage: Store Klingerit cardboard gaskets in a dry and clean place, away from direct sunlight and sources of heat and humidity. In addition, avoid placing heavy objects on the gaskets to prevent them from deforming.

- Adequate cleaning: Before installing a Klingerit cardboard joint, make sure that the joint surfaces are clean, dry and free of any debris or impurities. Surfaces can be wiped with a clean, dry cloth or a suitable solvent.

- Proper installation: Follow the manufacturer's installation instructions to ensure that the gasket is correctly positioned and properly tightened. Use proper tools and avoid over-tightening bolts to prevent damage to the gasket.

- Periodic inspection: Perform periodic inspections of Klingerit cardboard gaskets for any signs of damage or wear. If any damage is detected, replace the gasket immediately.

WHEN DOES A KLINGERIT GASKET HAVE TO BE REPLACED?

There are several signs that a cardboard Klingerit gasket is unusable and should be replaced. Some of the most common signs are as follows:

- Deformation or wear: If the cardboard Klingerit gasket exhibits significant deformation, cracking, or areas of wear, this indicates that the gasket does not fit properly and cannot provide an effective seal.

- Loss of elasticity: If the cardboard Klingerit gasket loses its elasticity, it may not seal properly and allow leakage at the connections.

- Leakage: If fluids or gases leak through the cardboard Klingerit gasket, this indicates that the gasket is damaged or does not fit properly and must be replaced.

- Damaged contact surface: If the contact surface of the cardboard Klingerit gasket is scratched, worn or contaminated, it will not seal properly and must be replaced.

- Expired useful life: If the cardboard Klingerit gasket has exceeded its recommended service life, it should not be used as it may not provide an adequate seal.

With a wide range of sealing materials and designs available, KLINGERIT gaskets can be tailored to the specific needs of any industrial application and with the experience and technical expertise of Vargort en el suministro de juntas Klingerit de cartón, contarás con soluciones a medida y un soporte técnico completo para tus proyectos industriales, asegurando un sellado seguro y eficiente en cada aplicación.

If you have any need for this material, do not hesitate to contact us. We will help you in the choice of the material as well as in the design of prototypes or mass production.